Marco Diani

Contatti

Telefono: 02.2399.8208

Skype: marco.diani88

E-mail: marco.diani@polimi.it

Engineering Design and Manufacturing for the Industry of the Future

Relatore: Prof. Marcello Colledani

Tutor: Prof. Paolo Pennacchi

Università di Provenienza: Politecnico di Milano - Ingegneria dei Materiali e delle Nanotecnologie

Titolo della Tesi: Cyber-Physical System for the control of size-reduction processes to enable cross-sectorial circular economy

Cyber-Physical System for the control of size-reduction processes to enable cross-sectorial circular economy

Introduction

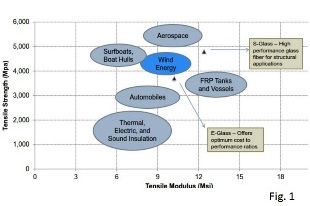

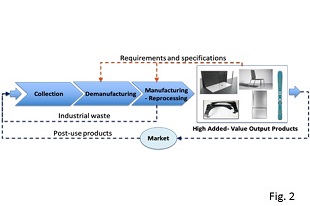

Circular Economy is indicating the route for a new paradigm in which profits and sustainability are not in conflict, but they cooperate to improve and grow up each other [1]. A cross-sectorial approach, in which recovered material from one sector can be reused in high-added value products of another sector [2], can enable new circular value-chains. In this view, size-reduction processes play the most important role.

Objectives

Focusing on size-reduction step, the first stage of a recycling process, the characteristics of output particles depend on requirements and specifications of high added-value products embedding the recycled material. As a consequence, the objective is to maximize the fraction of particles respecting material specifications minimizing the costs to obtain them through the control of size reduction processes.

Results

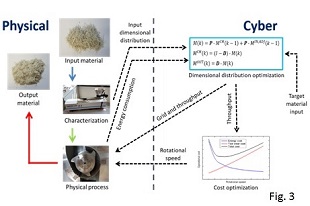

A two-step optimization process has been developed and implemented for the optimization of shredding processes. The first step is dedicated to the dimensional distribution optimization, resulting in a minimization of material loss (with the possibility to increase the quantity of material also in a specific interval) [3]. The second step allows a continuous cost minimization, resulting in recycled material competitiveness [4].

The approach has been validated on an industrial case in glass fiber reinforced plastics sector. By implementing the CPS solution the company would demanufacture and re-use an 81% higher throughput of material at 66% lower cost, also reducing the fraction of non-reusable materials that would be scrapped of about 30%.

Conclusions

The proposed solution showed its potentiality to enable cross-sectorial approach of new circular value-chains in composite sectors, moving waste from problem to resource. This approach can be applied also in different waste flows, both present (as printed circuit board or plastic) and future (as Li-ion batteries). In addition, the developed system is able to rapidly and robustly react to increases in market prices or lack of raw materials, as in the last year pandemic situation.

References

[1] E. MacArthur et al., Towards the circular economy, Journalof Industrial Ecology, 2:23–44, 2013.

[2] A. Mittal et al., Trends and opportunities for compositematerials in wind blade manufacturing, 2015

[3] M. Diani et al., A comminution model with homogeneityand multiplication assumptions for the waste electrical andelectronic equipment recycling industry, Journal of CleanerProduction, 211:665–678, 2019

[4] M. Diani, M. Colledani, Cyber-Physical Systemsformalization in de- and remanufacturing and application tosize reduction stage, Procedia CIRP 90, 483-487