Bin Fu

Contatti

Telefono: 02.2399.8663

Skype: fubin_swjtu@qq.com

E-mail: bin.fu@polimi.it

Sustainable Mobility

Relatore: Prof. Stefano Bruni

Tutor: Prof. Giorgio Colombo

Università di Provenienza: Southwest Jiaotong University - Vehicle Engineering

Titolo della Tesi: Active Suspension Technologies of Railway Vehicle

Active Suspension Technologies of Railway Vehicle

Introduction

Active suspension is an advanced concept in vehicle engineering, in which standard passive suspension components are combined to mechatronic components such as sensors, controllers and actuators, enabling a substantial improvement of vehicle dynamic behaviours, meeting the new demands of higher speed, better ride comfort and lower maintenance cost of rail vehicles[1]. Active steering can significantly improve curving behaviours but has not been applied in service due to two issues to be solved. The safety issue is concerned as the system may fail in service and cause critical impacts. The cost-benefit issue decides to which extent the technology is worthwhile from the viewpoint of business value, which however is challenging to estimate. Besides, with the trend of railway vehicle light weighting, car-body structural vibration is posing a new challenge to the vertical ride comfort, which is also expected to be solved via mechatronic suspensions.

Objectives

The overall goal of the thesis is to develop active suspension technologies, providing practical solutions to improving the curving behaviour and vertical ride comfort of a rail vehicle, as shown in Fig.1 (Rail vehicle model). In this thesis, the first and second objectives are to study the two open challenging issues of active steering that have so far hindered its application: safety insurance and cost-benefit estimation. The third objective is to study the mechatronic suspensions to meet an emerging demand of attenuating the car-body structural vibration.

Results

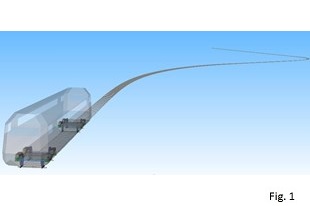

To ensure the safety of active steering, a methodology is proposed based on Risk Priority Number (RPN) to evaluate the fault-tolerant capability against failure modes. Vehicle multi-body simulations are performed to assess the impact of typical failure modes quantitatively. Nine schemes of active steering are proposed, as shown in Fig.2 (Fault-tolerant designs of active steering) considering three principles for improving fault tolerance: (i) adding passive spring as backup; (ii) implementing redundant actuators and (iii) reducing the number of actuators through mechanical linkages. The RPN values of the nine schemes in failure modes are summarized in Fig.3 (RPN values of proposed nine schemes), showing that the redundant actuators can provide the overall best fault-tolerant capability[2].

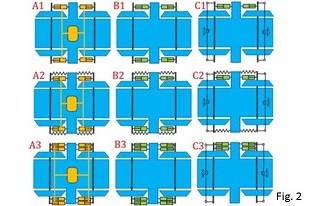

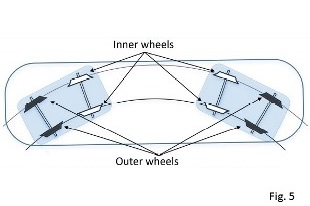

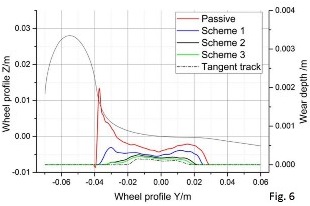

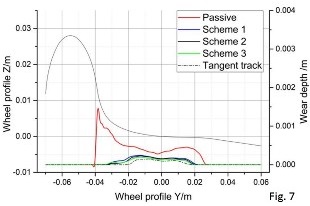

The assessment of the cost-benefit ratio of active steering is realized using a wheel wear calculation program. The removed material over wheel surface is simulated with the presence of active steering in different track layouts. Moreover, three control schemes for active steering are compared in terms of wheel wear evolution, and conclusions about their suitability are drawn, see Fig.4 (Wear depth at one contact patch),5 (Outer and Inner wheels in curves), 6 (Removed material in three steering schemes for Outer wheels) and 7 (Removed material in three steering schemes for Inner wheels)[3,4].

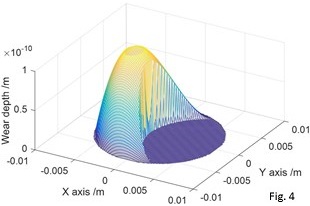

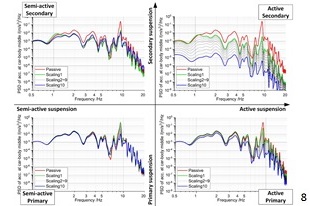

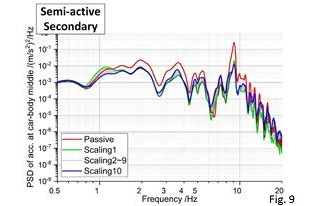

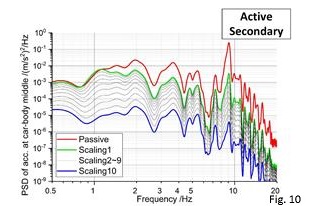

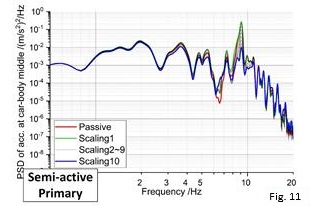

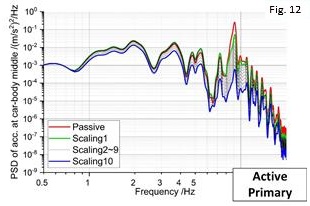

This thesis also explores four schemes including active and semi-active technologies in secondary and primary suspensions, with LQG and H8 controllers. The comparison of four schemes based on a 9-DOF vehicle model is summarized in a four-quadrant diagram, see Fig.6 (PSDs of car-body vertical acceleration at car centre, based on 9-DOF vehicle model), showing that the full-active secondary suspension is the most effective solution, whilst the semi-active primary suspension can also considerably mitigate the carbody bending mode[5].

Conclusions

(i) An evaluation methodology was proposed to assess the fault tolerance of active suspensions. Nine faulttolerant designs for active steering were compared, showing that applying redundant actuators has the overall best performance.

(ii) The wheel wear evaluation of vehicle with active steering was performed. Suitable strategies were defined, showing satisfactory steering performance and enabling practical implementation.

(iii) The features of four mechatronic suspension schemes were analysed to improve the vertical ride comfort, providing a basis for the selection of the bestsuited scheme in terms of the trade-off between performance and complexity of implementation.

References

[1] B. Fu, R.L. Giossi, R. Persson, S. Stichel, S. Bruni, R. Goodall, Active suspension in railway vehicles: a literature survey, Railw. Eng. Sci. 28 (2020) 3–35.

[2] B. Fu, S. Bruni, Fault-tolerant design and evaluation for a railway bogie active steering system, Veh. Syst. Dyn. (2020) 1–25.

[3] B. Fu, S. Hossein-Nia, S. Stichel, S. Bruni, Study on active wheelset steering from the perspective of wheel wear evolution, Veh. Syst. Dyn. (2020) 1–24.

[4] B. Fu, S. Hossein-Nia, S. Stichel, S. Bruni, Wheel wear evolution of solid-axle wheelset with active steering, Second International Conference on Rail Transportation (ICRT 2021), July 2021, Chengdu.

[5] B. Fu, S. Bruni, An examination of alternative schemes for active and semi-active control of vertical car-body vibration to improve ride comfort, Proceedings of the Institution of Mechanical Engineers Part F-Journal of Rail and Rapid Transit, 1-20, 2021.