A new high-pressure Impact Innovations 5/8 cold spray unit has been recently installed in our labs at the Department of Mechanical Engineering, with Prof. Mario Guagliano as scientific supervisor.

Cold spray is a powder deposition technique exploiting kinetic energy. It differs from other technologies because it doesn’t use thermal energy to melt the powder.

Indeed, the cold spray process is based on the supersonic acceleration of the metal powder over the critical value. Even though the matter is still discussed within the scientific community, the high strain rate of plastic deformation and microstructural mechanisms allow the adhesion phenomenon to occur when the powder in its solid state. Through this mechanism the powder adheres when colliding with the substrate and progressively create a thicker coating. Materials able to undergo plastic deformation, meaning it must be ductile, is the only requirement for adhesion to occur. Cold spray turns out to be very appealing since it finds its application to most of the metals.

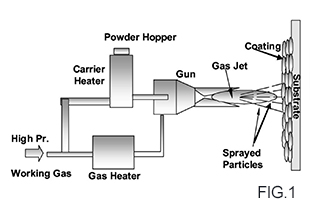

Picture 1 represents a schematic illustration of the process: a pre-compressed and heated gas is injected in a de Laval nozzle to maintain the powder flux to its optimal conditions, so to adhere to the substrate and gradually build a layer without limits of thickness. This process can benefit both to the creation of thin coatings and to the manufacturing of bulk components.

The cold spray has features that make it appealing for diverse industries, and its applications are increasing. For example, the high rate of deposition and the lack of needing a controlled atmosphere chamber make it also suitable for additive manufacturing to produce massive components along with temperature-sensitive materials. On the other hand, it also allows mixing different powders, like metal and non-metal, to create materials with customised features according to its functions. It also allows metallising polymeric surfaces without undergoing any chemical process.

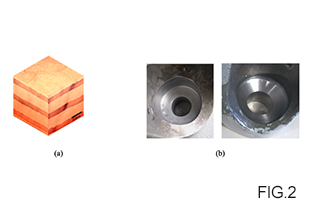

Moreover, it allows to repair locally or widespread fractured pieces to reset and improve their original properties. For this reason, it turns out to be excellent in re-manufacturing and sensoring components in the Industry 4.0 framework.

“My research group – said Prof. Guagliano – has been working with cold spray for several years now. We started by simulating and optimising the process according to the material. Later on, we moved to experimental customisation of the coating properties and components manufactured by cold spray. Along with other 13 partners, including Airbus, we also coordinated a European Project to apply cold spray when repairing aeronautical structural components. In particular, we dealt with the mechanical characterisation of damaged components and repaired via cold spray, underling whether possible to reset the original performance status of components.”

“We recently started new research activities supervised by PhD. Sara Bagherifard, on bimodal materials obtained with cold spray and by additive manufacturing applications” – he added. “The installation of the 5/8 plant at the Department of Mechanical Engineering allows us to complete the competence we have on this matter and to increase the number of research projects and collaborations to which we can give our contribution”.

As a matter of fact, the project ATLAS (Advanced Design of High Entropy Alloys Based Materials for Space Propulsion) has just started, coordinated by Prof. Guagliano and founded through the programme EC-H2020. The project objective is to develop and customise the cold spray process for HEAs (High Entropy Alloys), which should improve the performance and efficiency of the next generation of space propulsion systems.

Moreover, sponsored by MIUR as part of the project relevant at a domestic level (PRIN), the project COSMEC (Cold Spray of Metal-to-Composite, scientific manager Prof.ssa Chiara Colombo) has reached its midterm.

New activities with Lucchini RS Group have also just started to evaluate the usage of cold spray in the railway field to repair damaged structural components and develop controlled porosity coatings for orthopaedic implants to facilitate osseointegration.

Finally, the research group, with Sara Bagherifard, Chiara Colombo, Asghar Heydari and some PhD students, is also studying the application of cold spray to design bimodal materials with functionalized properties and for the generation of controlled porosity coatings for orthopedic prostheses, in order to facilitate osseointegration.