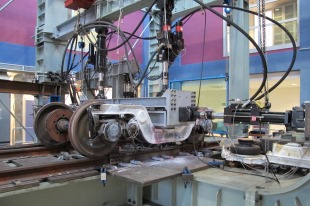

Part of our Railway Engineering Lab, the bogie test rig provides a series of test rigs to test and characterize the features of different railway vehicles and their sub-systems - such as bogie frames, wheelsets, pantograph, suspensions, axle boxes, etc.

In particular, the test rig for bogie frames allows possibility to adapt its layout to house every existing railway bogie currently used on our railway, tramway and underground lines allowing static, and fatigue tests compliant with the European standard EN 13749.

As required by the standard, the first objective of the test it is accurately recreate the real working condition the bogie is designed for. The design requirements depends on: the type of bogie and its structure, the ballast condition, the geometry of the track, the cant angle, the forces exchanged when negotiating curves, acceleration-deceleration and exceptional cases such as a collision.

The testing method consists in applying on the structure under test (i.e. the bogie frame and its subsystems) static and dynamic loads and measure their deformations. Moreover, a series of nondestructive inspections (i.e., magnetoscopic or dye penetrant methods) are carried out on the specimen under test to monitor the nucleation of cracks and eventually their evolution during the fatigue test.

During the setting up of the test the actuators which transfer the loads on the structure are connected to the bogie frame by means of specifically designed interfaces. The strain gauges, for the measurement of the consequent deformations, are installed in specific measurement points defined by the designers of the bogie frame. The strain gauges measuring system allows the measurement of up to 120 independent channels.

During the test, it is possible to control simultaneously the hydraulic actuators involved (up to 12 channels), each with different loads less or equal to 1000 kN. All actuators are controlled via feedback both in displacement and in force through servo-valves and a specific control system to guarantee their adequate performance during fatigue and static tests.

The test rig is designed to apply loads on the boogie mounted on the wheelset using the original primary suspensions to replicate as accurately as possible the loads distribution on the ground.

The test rig allows on the following performances:

- The variation of gauge values from 900 mm up to a maximum of 1600 mm.

- The housing of bogies equipped with wheels with a maximum wheel diameter of 1200 mm.

- The housing of bogies with a number of wheelsets between 2 and 5.

- The placement of bogies with a wheelbase between two adjacent wheelsets from 700 mm to 3000 mm.

Every year, DMEC receives several requests from train companies (like Alstom, Bombardier, Hitachi Rail to mention a few), for the execution of tests aimed at both the approval of new bogie design and the verification of particular load conditions to improve the design phase.