Increase awareness in environmental issues have triggered interest in EU market in development of innovative lightweight structural steels for various applications. The austenitic Fe-Mn-Al-C alloys have attracted tremendous attention. Although they could be hard to process, they are characterized by exceptional combination of high strength and high ductility, and additionally they do not require expensive or strategically sensitive alloying elements such as Mo, Cr and Ni.

The aim of DELIGHTED project is indeed to gain fundamental understanding on design principles and properties necessary to apply these alloys in the industrial application.

The topics addressed by DELIGHTED project with such final goal are:

- effect of the steel chemical composition on the microstructure evolution during hot rolling with focus on recrystallization, precipitation and growth of particles and development of crystallographic texture;

- crack prevention during hot rolling to develop suitable thermo-mechanical processes;

- kappa-carbide precipitation and growth kinetics in austenitic matrix in relations to chemical composition and thermal history;

- relationship between microstructural state and technological properties (e.g., fracture toughness, fatigue resistance and weldability);

- development of analytical methods able to predict mechanical properties;

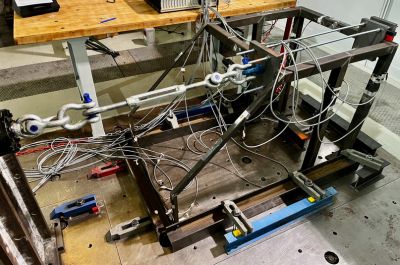

- design, manufacturing and testing of a ROPS prototype employing the developed alloy.

The Mechanical Department is part of this project and is in charge to study the material formability and weldability properties along with the production of a real prototype of roll over protection structure and its testing.

The project is structured over 44 months and is funded by the RFCS horizon2020 call.