What is WP3 of the LIS4.0 project about? Which are the challenges it must face?

The WP3 "Metastructures" is dealing with the study of design tools /properties / applications of cellular materials based on a regular micro-structure called unit cell that is periodically repeated in the space to obtain a meta-material characterized by a regular combination of tiny structures (beams /surfaces /masses) joined together. The physical length of the unit cell is shorter than the wavelength of interest (loads in a structure, heat and sound waves) to obtain "metamaterials", that are solids with 'homogeneized' properties not existing in nature. They are 'novel engineered materials' with an higher degree of complexity respect to traditional composite materials.

The challenges are to design with/manufacture and apply new metamaterials that become 'multifuctional' because they can combine lightweight with other properties. The first example can be a lattice material with a limited heat conductivity that we have applied in a space component (Fig. 1a) or other surface/sheet based cells that allow a very efficient heat exchange between 2 liquids (Fig. 1b). At the level of structures/components a 'meta-structure' can then be designed/obtained with the hybrid combinations of different material solutions.

The challenge, surely aligned with our mission of mechanical engineers, is to transfer the conceptual design of the metamaterials/metastructures to real applications, taking into account the design constraints at a component level and the real properties of the new materials (led by the rapidly evolving manufacturing cycles), especially considering multi-material combinations. The edge of current developments for industrial applications is the possibility to eventually qualify the industrial components that have been designed with such a degree of novel solutions.

Which innovative instrument/approaches are required to address the design and development of products based on meta-structures?

The tools needed for design and development of components of metamaterials and metastructures should enable the engineer to handle models /structures characterized by an high degree of complexity. Efficient tools, instead of a massive application of traditional computational tools, are aimed at reducing the scale of the model along different lines:

- ontology-based models able to overcome the impossibility to obtained detailed FE models of components with different metamaterials;

- homogeneized failure criteria that allow us to 'build' a library of cellular materials available for the design of different applications under static and fatigue loading. Such homogeneized models for describing the mechanical behaviour (elastic, non-linear monotonic and cyclic) are based on the real modelling of the as-manufactured cells, thus allowing to inherently consider the anomalies/deviations respect to ideal configurations;

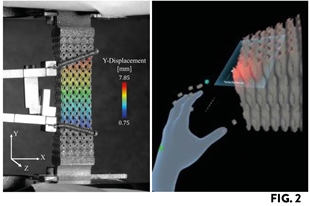

- AR/VR tools that could allow the engineer to handle efficiently the CT scans of complex metamaterials and find/analyze the defects of manufactured parts for a quick qualification of parts 'ready to fly' (Fig. 2).

Which were the main prototype developed?

The prototypes that have been developed are:

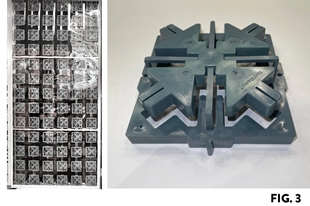

- a sound-absorption panel that can easily, and has been proven to, reduce noise transmission by more than 8-10dB (see Fig. 3);

- an innovative arm for a McPherson suspension made of an hydrid polymer/metal structure. In detail the additively manufactured polymeric part has been optimized considering the real stresses in the component together with the suitable joining solutions for ensuring the desired structural response (see Fig. 4);

- an hybrid (combination of solid skins and cellular parts) space component manufactured by additive manufacturing, Fig. 1a: the cellular parts have been optimized for the structural and thermal response of the entire component adopting the homogeneized approaches developed in WP3.