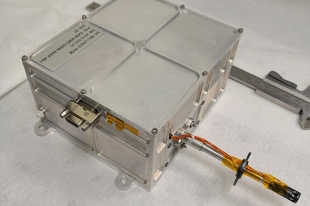

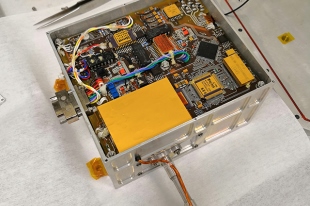

Next stop: Mars! Yes, the red planet. Not sooner than a few weeks ago, the final integration was made on the scientific instrument “MicroMED”, a dust analyzer developed at the MetroSpace Lab. This lab of the Department of Mechanical Engineering is located on our campus in Lecco. Here scientists carry out the design and development of instruments for space applications and, sometimes, also their manufacturing, integration, and qualification. MicroMED will fly to Mars onboard the ESA-Roscosmos ExoMars 2022 mission. MicroMED is part of “DustSuite”, a series of scientific instruments aiming at studying martian dust, which will be used by the Russian Space Agency Roscosmos. The MicroMED project has been developed in collaboration with the astronomical observatory of the INAF, located in Capodimonte, and the INTA, Institute of the Spanish Space Agency, and thanks to the funds POR-FESR2014-2020 received by Regione Campania and by ASI. Even though it started way later than expected, in less than three years the project resulted in two developed, assembled, and qualified flying models of the instruments.

MicroMED is only one of the many projects currently under development in our Laboratory. For example, also VISTA (Volatile In Situ Thermogravimeter Analyser) is currently being assembled, since last June it passed the PDR, the first revision carried out by the ESA. VISTA, a quartz crystal microbalance (QCM) selected as a payload of the Milani satellite of the HERA mission of the ESA, developed in cooperation with the INAF-IAPS in Rome and the National Research Centre. The objective will be to measure the level of molecular contamination onboard the satellite and study its emission during the flyby phases as planned around the Didymos asteroid. The current step of the project involves the creation of an engineering model to be tested and delivered by the end of next spring and flight models for the Milani satellite. However, the team must work for two more years to build the final model ready for the launch, scheduled in 2024. There are many steps before the launch, for example, the qualification of the engineering model, manufacturing of the flight models, integration, functional testing, and acceptance tests.

Manufacturing space instruments is not a usual activity in the laboratory. Its main activity focuses on developing innovative space instruments, proving their feasibility at the initial phases of the mission development. In this perspective, the Lab was responsible for the feasibility design of the MAJIS instrument, within the JUICE (ESA) mission framework, whose manufacturing is now performed by Leonardo Company.

From an engineering point of view, feasibility studies are quite challenging since they require the development of different design solutions suitable according to the features of each mission. Modelling thermal and mechanical systems of scientific instruments and payloads, which are starting points for both the development itself and feasibility study, always demands experimental validation, given the extreme and unusual conditions object of the analysis. Therefore, the MetroSpace Lab stands out for its Thermal Vacuum Chamber (TVC) and measurement instruments, which allow evaluating the performance of the instruments in environmental and stress conditions typical of each phase of the currently analysed mission.

But if one project comes to an end, more are about to start, especially those focusing on the next destinations of interest for Space Agencies. The MetroSpace Lab is studying the development of Daedalus-CAM, a panoramic camera to observe Moon caves for a future ESA project, and two innovative imaging spectrometers: the RIIFS, a Fourier-Transform Spectrometer immune to vibrations; and the FISPEX, an integral field spectrograph able to produce hyperspectral images after a single acquisition. These two instruments are ideal candidates respectively for surface exploration through a Rover and space exploration.