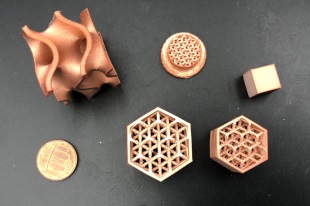

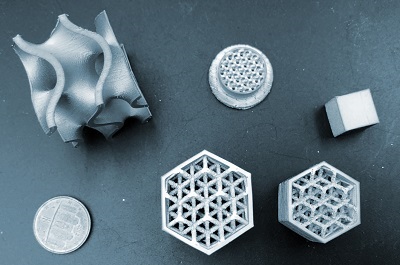

Copper printing enabled with the Studio System+ installed at DMEC at Polimi. Pure Copper expands the currently available material portfolio including 17-4 Ph Steel and 316L steel. The research group led by prof. Colosimo is now testing new high-performance designs components made of copper, that support the incorporation of lightweight structures or internal conformal cooling channels not achievable with traditional manufacturing, to improve heat transfer. Research is also conducted to study the applicability of these 3d printed components for spatial application.

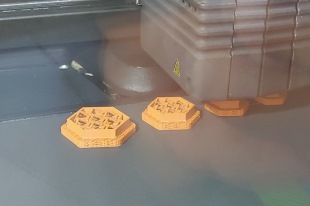

Manufacturing parts featuring complex geometries and made by pure copper is now possible with the BMD process implemented in the Studio System+ system installed at DMEC Pure Copper expands the currently available material portfolio including 17-4 Ph Steel and 316L steel. The parts are printed by using feedstock extrusion process and then are debound and sintered in furnace using a gas mix of Argon+3%Hydrogen, reaching low porosity and excellent conductive properties. Thanks to the 0.25 mm nozzle diameter, the achievable printing resolution guarantees the printability of fine features and highly accurate components, that can be bigger than 150 mm and 1kg in sintered state. Heat sinks, Heat Exchangers, Electrical Motor and Power-Grid components or Tooling components are among the most interesting 3d printing applications of pure copper for heavy industries and consumer products. The research group led by prof. Colosimo is now testing new high-performance designs components made of copper, that support the incorporation of lightweight structures or internal conformal cooling channels not achievable with traditional manufacturing, to improve heat transfer. Research is also conducted to study the applicability of these 3d printed components for spatial application.