The idea of a Smart Wheelset for High-Speed trains, able to monitor and transmit real time data on its health status, was born in 2017 from a collaboration between the Department of Mechanical Engineering of Politecnico di Milano and Lucchini RS, a company specialized in the production of rolling stocks.

The project is developed in a wider framework that saw, during the last years, a constant growth of interconnected systems for structural monitoring of mechanical components, also in the railway sector, and that is driving an enormous growth in predictive maintenance, achieving higher standards of safety and security in the railway transport system.

The goal of the research is to create an integrated sensor system inserted in the high-speed trains axle to perform monitoring operations with the objective to allow predictive maintenance of the mechanical components and avoid accidents or unexpected stoppage of the line. The research is divided into two subsequent parts:

- a theoretical study of different defects on the wheelset of a high-speed train by means of numerical simulations with a Multi-Body model software. This first part allows to define ad-hoc algorithms for the identification of different defects on the wheelset, starting from acceleration measurements in the 3 directions (vertical, lateral and longitudinal).

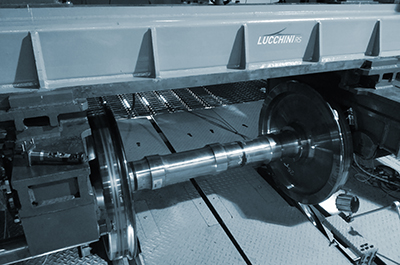

- an experimental campaign on the Lucchini test bench BU300 in Lovere which allowed to verify the developed algorithms and to tests the prototype in a real-like environment. The different defects have been reproduced on a real wheelset thanks to the precious contribution of the technical department of Lucchini RS, and the wheelset has been tested, in presence of the defects, up to the maximum rotational speed allowed at the test bench, corresponding to an equivalent vehicle speed of 300 km/h.

The project has led to the realization of a first sensor prototype able to perform the automatic identification of some of the main defects that can affect the wheels: Wheel-Flat, Out-of-Roundness, wear of the wheel profile and crack propagation. In particular, the identification of the presence of a crack in the axle well before that it reaches high dimensions that can endanger the structural integrity of the vehicle is of fundamental importance to increase the reliability of the railway lines and the safety of the railway sector.