The Cable Dynamics Laboratory is part of the Department of Mechanical Engineering labs and enables the experimental testing for the evaluation of the dynamic properties of cables, dampers and spacers which represent the main mechanical components of High Voltage Transmission Lines. In this field in fact, the knowledge of the cable and damping devices mechanical properties is fundamental to correctly estimate, through numerical models, the overhead transmission line dynamic response to the wind excitation. In particular, conductor self-damping together with damper dynamic stiffness and spacer-damper stiffness and damping properties are evaluated on laboratory test spans and are used as input in numerical models to assess both the conductor plus damping devices dynamic performances and to optimize the damping devices design.

The laboratory allows both customized tests and standard tests carried out according to the main International Standards. In particular, accredited ISO tests “Stockbridge Type Dampers Dynamic Characterization” (ISO9001:2008 certification) and “Stockbridge Type Dampers Effectiveness Test” (ISO9001:2008 certification) can be performed.

The main activities carried out are represented by the cable self-damping tests, which can be performed according to different methods, namely the Decay Method, the Power Method and the Inverse Standing Wave Ratio. Cable plus suspension clamp fatigue test can be assessed by inserting a suspension clamp along the span in order to reproduce a sufficiently long active span. At the end of the test, a cable sample near the suspension clamp is cut in order to verify if some strand failures have occurred during the test.

Thermal tests are very important especially for High Temperature Low Sag conductors, which are nowadays more and more being used to uprate the existing transmission lines (Figure 2a). The aim of these tests is to define the linear coefficient of thermal expansion and the sag curve/knee-point temperature of the conductor.

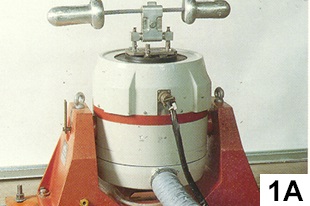

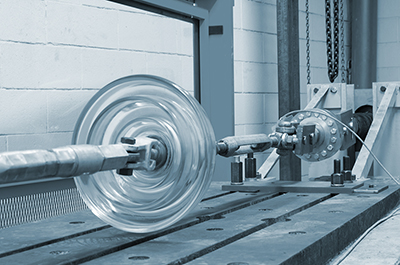

The Stockbridge dampers dynamic performances can be evaluated in two different ways. The damper can be mounted on the shaker in order to compute the damper characteristic curve (Mechanical impedance/Dynamic stiffness with imposed constant speed or constant displacement) (Figure 1a) or effectiveness tests are performed to evaluate the cable plus damper dynamic response (Figure 1b).

Tests devoted to obtaining the spacer-dampers dynamic characterization are carried out too (Figure 2b). Stiffness and damping properties are evaluated at high and low temperature and aeolian vibrations and subspan oscillations are reproduced during fatigue tests. Moreover, simulated short circuit tests and slip tests can be performed.

A fundamental aspect of the Cable Dynamics Laboratory is represented by the facility and its measurement apparatus. The laboratory span is 50 m long, and it is endowed of a Programmable Logic Control (PLC). The conductor tensile load is controlled by means of an electromechanical actuator UNIMES TP7010 MBD with electrical motor 7.5 kW 750rpm and measured through a load cell U10M/250 kN + HBM Scout 55. To make the cable vibrating a Gearing Watson electro-dynamic shaker plus amplifier (V617/DSA4-8k) and a B&K 1050 controller are used while for conductor heating and thermal tests 5 TDK Lambda GEN25-400-3P400 current suppliers (for a total power of 50 kW) are employed. The instrumentation includes a number of sensors, among which piezo-accelerometers B&K 4508 with power amplifiers PCB 480E09, Kistler piezoelectric load cells, strain gauges and conditioning modules, laser transducers and other displacement transducers and temperature sensors. Various sizes of hydraulic actuators and load cells plus MTS Flex Test Digital Controllers are available for specific tests such as slippage ones.