The ICEBERG project (Improved elastoCaloric Effect BEyond tRaditional thermal management) has been awarded funding under the PRIN (Projects of Significant National Interest) call. This groundbreaking research initiative aims to develop next-generation shape memory alloys (SMAs) with enhanced elastocaloric properties, paving the way for innovative and efficient solid-state refrigeration systems.

SMAs are functional materials that exhibit a stress-induced martensitic phase transformation, making them highly suitable for elastocaloric cooling applications. Over the years, research has progressed from binary NiTii intermetallics to more complex ternary and quaternary systems, as well as Cu-based and magnetic alloys. The ICEBERG project focuses on further improving the elastocaloric effect by exploring novel ternary and quaternary alloys based on the NiTi system.

Led by expert research groups from the National Research Council (Dr. Elena Villa) and Department of Mechanical Engineering of Politecnico di Milano (Prof. Riccardo Casati), ICEBERG will leverage state-of-the-art processing techniques to develop and optimize these advanced materials. Mini-scale ingots will be produced through vacuum arc remelting and subsequently processed into ribbons and wires. Their chemical composition and microstructure will be fine-tuned to maximize elastocaloric effect efficiency, measured through key performance indicators such as temperature change, entropy change, and coefficient of performance.

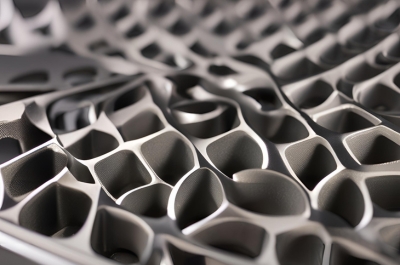

The project will also explore additive manufacturing as an alternative production method for elastocaloric materials. Conventional fabrication techniques often face challenges such as high strain hardening, limited workability, and excessive tool wear, which can hinder the manufacturability of SMAs. By utilizing laser powder bed fusion, ICEBERG aims to overcome these limitations, enabling the production of near-net shape components with complex geometries and enhanced cooling efficiency. A novel high-throughput screening method based on powder mixing will facilitate the development of novel alloys optimized for AM processing.

The ultimate goal of the ICEBERG project is to fabricate miniature solid-state refrigerators with high surface-to-volume ratios, leveraging the unique capabilities of AM to enhance heat exchange and elastocaloric performance. By bridging the gap between material science and advanced manufacturing, ICEBERG seeks to establish a new benchmark in the field of SMA-based refrigeration.

Through their complementary expertise in metallurgy, shape memory alloys, and additive manufacturing, the research teams at CNR and Politecnico di Milano are set to push the boundaries of elastocaloric cooling technology. The success of ICEBERG could significantly contribute to the development of eco-friendly and energy-efficient refrigeration solutions, reducing reliance on conventional cooling methods and their associated environmental impact.