Description:

The Advanced Manufacturing Laboratory is equipped with stateof-the-art research facilities with industrial, prototypal, and experimental systems, testing and characterization equipment as well as dedicated software packages. In the laboratory, the complete material transformation phases are represented from process to its qualification to the complete production system. Process feasibility, optimization, and control as well as production systems design and performance enhancements are covered within the research.

References:

ABB, Alcar Ruote SA, Ansaldo Energia, ASI, ATS Team3D, ATV, Baker Hughes, BLM Group, Camozzi Ingersoll Machine tools, Carel, CGTech, CSM Rina, Comau, ESA, GE Avio Aero, Hitachi Rail, Huawei, IMA Automation ATOP, Intermac, Kern, Kyocera, Lima Corporate, MCM, R.F. Celada, Saipem, Sandvik Coromant, Siemens, Sovema, Standex, Technoprobe, Tenova, Trumpf, Yasda, WatAJet

Instruments & Facilities:

- BLM Group Adige Sys LC5 combined laser sheet and tube cutting system with 6 kW fiber laser

- BLM Group Alfetta flexible robotic laser welding cell with 6 kW fiber laser and wobbler head

- Lasers for e-mobility cell for remote welding, stripping, cleaning, and ablation solutions with 1 kW single mode fiber, 100 W green, and 50 W ns-pulsed fiber lasers

- Laser Induced Forward Transfer system for high precision multimaterial additive manufacturing

- Laser micromachining cell with high power fs, ps, and ns pulsed laser sources

- Qilin hand-held laser welding system with 3kW fiber laser

- Yasda YMC 650 + RT20 High precision 5 axis CNC machining centre

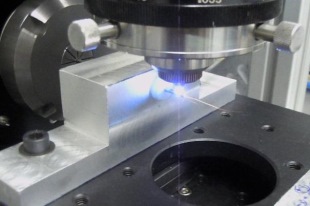

- KERN EVO Ultra precision 5 axis CNC machining centre

- The Digital Twin Lab for physical simulation of production systems

- Tecnocut IDRO 1740 water Jet cutting system with Flow intensifier pump up to 380 MPa

- Alicona Infinite Focus micro coordinate measurement system (resolution up to 10 nm)

- Zeiss Prismo 5 VAST MPS HTG coordinate measuring machine (E0,MPE = 2,0 + L/300 µm)

- North Star Imaging NSI X25 micro computed tomography system

- FLIR X690Xsc MWIR high speed thermal camera with acquisition rate up to 20.000 fps

- Additive manufacturing systems (see “Additive manufacturing” for more details)

Activities:

The research topics include the following:

- Additive manufacturing process improvement, monitoring, control, and novel solutions

- Advanced machining and machine tools

- Deformation of metals with conventional and flexible tools

- De-manufacturing systems for circular economy

- Geometric product specification and verification

- In-situ process monitoring and intelligent data analysis

- MI_crolab – Micro Machining Laboratory

- Performance evaluation and optimization of manufacturing systems

- SITEC Laboratory for Laser Applications including cutting, welding, microprocessing, cladding, heat treatment

- Virtual manufacturing and simulations of manufacturing processes

- Water Jet Lab for process improvement and novel solutions