Description:

The laboratory is equipped with analytical instruments and testing devices for the investigation of material properties. Optical and electron microscopes equipped with EDX and EBSD detectors are available for microstructure and failure analysis. Thermal, physical and chemical properties of materials are characterized by a set of analytical instruments, including a dilatometer, a laser-flash analyzer, a differential scanning calorimeter, an optical emission spectrometer, an oxygen and nitrogen analyzer, and a platform for the analysis of thermoelectric properties of materials. Properties of material surfaces and coatings are investigated by a pin-on-disk tribometer, a scratch tester, and an instrumented microhardness tester.

References:

Brembo, Ferrari, Avio, Sandvik, Tenaris Dalmine.

Instruments & Facilities:

- Zeiss Sigma 500 Field Emission Scanning Electron Microscope equipped by the Oxford Ultimax 65 Energy Dispersive X-ray Analysis (EDS) and the Oxford C-NANO Electron Backscattered Diffraction (EBSD) detectors

- Zeiss EVO 50XVP Thermionic Scanning Electron Microscope with the Oxford Inca Energy 200 X-ray microanalysis (EDS) detector

- Nikon Eclipse LV150NL light optical microscope

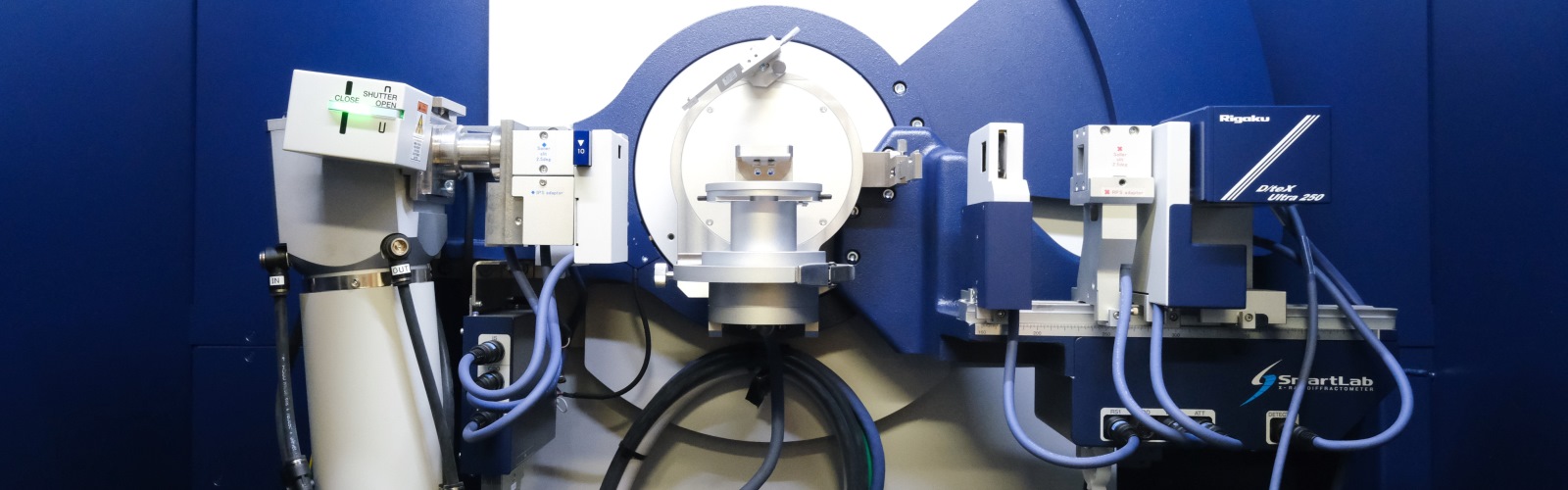

- Rigaku SmartLab SE powder X-Ray diffractometer for qualitative and quantitative phase analysis. The instrument is equipped with a Eulerian cradle for stress and texture analysis

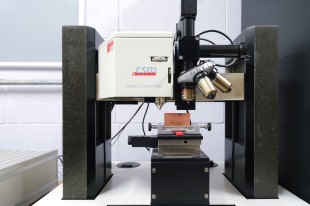

- StressTech X3000 X-Ray diffractometer for nondestructive measurement of residual stresses and retained austenite in crystalline materials. It also allows analysis of large mechanical components including in-situ applications, eg. pipelines and bridges

- Setaram DSC / GTA thermal analysis system equipped with furnace and rods for temperature cycles of up to 800 and 1600°C

- OES Bruker Q4 Tasman 130. Analyzable matrix: Fe, Al, Ni, Ti. Bulk samples. Minimum sample size = 25x25x0.5 mm

- LECO Oxygen and Nitrogen analyzer

- Vertical Dilatometer Linseis V75 with temperature ranges RT-900°C and RT 1600°C

- Laser Flash Analyzer Linseis LFA 1000/1600 for direct measurements of thermal diffusivity and indirect measurements of thermal conductivity in the temperature range RT-1600°C

- Seeback/TE Linseys LZT 1100. Combined LFA (thermal diffusivity) and LSR (Seebeck and resistivity) for cylindrical (up to 6 mm in diameter and max. 23 mm long), prismatic (2 to 5 mm rectangular and max. 23 mm long) and button-shape (from Ø12.7 to Ø25.4 mm) samples. Maximum temperature 1100 °C under He atmosphere

- CSM pin-on-disk tribometer

- CSM Microindenter instrumented microhardness (loads from 0,01 to 10 N) and scratch tester (load range 0.3 30 N)

- Foerster Sigmatest eddy current instrument that measures the electrical conductivity of non-ferromagnetic metals electrical resistivity measurements

- Heat flow probes, specifically the high-temperature FCR-200-M-K supplied by Wuntronic GmbH, with max service temperature 550°C and max heat flux range 15,800 W/(m2K), sensitivity 560 (W/m2)/mV

- Multimeter 7.5 digits Keithley

Activities:

- Microstructure investigation, failure analysis and quality control by optical and scanning electron microscopy. Texture analysis of crystalline materials by EBSD and XRD

- Chemical analysis by OES, EDX and LECO

- Analysis of phases and residual stresses by X-ray diffraction

- Thermal analysis by dilatometer, laser flash analyzer and differential scanning calorimetry

- Wear tests by pin on disk tribometer and analysis of coating adhesion by scratch tester