Description:

The Computer Vision and Reverse Engineering laboratory is specialized in the Reverse Engineering pipeline for study, research and industrial applications: 3D devices calibration and characterization, 3D acquisition and processing, redrawing of CAD models based on 3D data. The 3D capturing equipment permits to acquire industrial components, structures, Cultural Heritage objects with a wide range of geometries, sizes and materials.

References:

The laboratory has contributed to the production of reality-based 3D models for the following patrons:

- Scuola Normale Superiore di Pisa

- Comune di Milano Castello Sforzesco

- Comune di Milano Civico Museo Archeologico

Instruments & Facilities:

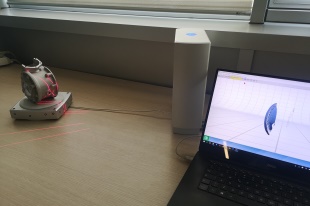

3D Scanners:

- Konica Minolta Vivid 9i

- GOM Atos

- NextEngine Ultra HD

- Artec Leo

- EviXscan 3D Heavy Duty Quadro 3D

- Structure Sensor

Coordinate Measuring System:

- Microscribe MX digitizer system

Professional Cameras:

- Sony

- Canon

Activities:

Camera calibration for photogrammetry and 3D Vision

- Radial distortions assessment

- Tangential distortion assessment

- Affine distortion assessment

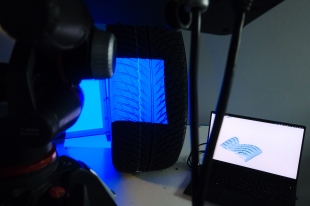

Active 3D range sensors characterization (Triangulation and TOF/PS) according to Committee E57 draft ASTM

- Global uncertainty assessment

- Precision assessment

- Accuracy assessment

3D acquisition and modelling based on:

- Traditional photogrammetry with sparse clouds

- SFM/Image matching with dense clouds/meshes

- Triangulation based laser scanning and dense mesh generation

- TOF/PS laser scanning and dense mesh generation

- CAD drawing on 3D data gathered manually or automatically

3D models optimization for Virtual Navigation

- Mesh optimization

- Texturing/Displacement mapping

- 3D segmentation