Description:

The laboratory is equipped with multi-range servohydraulic actuators and other facilities to perform tests on full-scale components and structures. The equipment includes servo-controllers, load cells, electrodynamic shakers, modular constraint systems, various transducers (pressure, temperature, displacement, acceleration, strain, acoustic waves, etc.), with dedicated signal conditioners and acquiring systems. A novel micro-compression device, compatible with a synchrotron, is available for multi-scale mechanical testing. The laboratory is supported by modelling capabilities (mainly numerical FE and CFD models) in order to replicate and extend experimental activities by means of “virtual tests” (predictive models).

Certifications:

The laboratory is compliant with Leonardo Helicopters quality standard requirements.

Tests on aeronautical components also for certification purpose (FAA) have been carried out in the laboratory.

References:

Leonardo Helicopters, Cifa, ENI, Pirelli, Ferrari.

Instruments & Facilities:

Special set-ups for full-scale component testing:

- Servo-hydraulic actuators (max force 1000 kN). Electrodynamic shakers (max force 25 kN)

- Controllers for servo-hydraulic actuators: single and multichannel (MTS 407, MTS Flex Test IIm, MTS Aero GT, MTS Flex Test SE, etc.)

- Constraint systems with treaded holes or grooves and steel beams to build customized frames for full-scale tests

Other equipment and devices:

- Load cells

- Displacement transducers

- Rotation transducers

- Pressure and temperature transducers

- Accelerometers

- Systems for data analysis

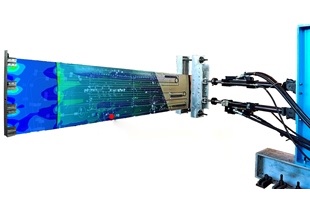

- Systems for strain measurements

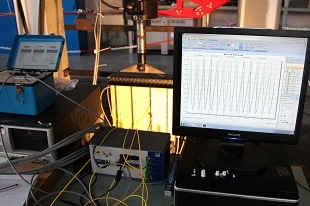

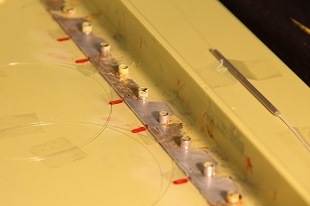

- Optical fiber interrogator with Military Standard environmental qualification (MIL-STD 810G)

- Multi-channel oscilloscopes

- Micro compression device suitable for small samples’ testing and compatible with synchrotron facility

Activities:

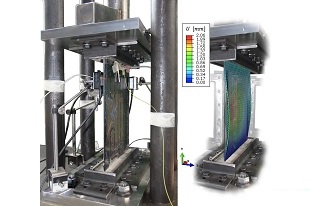

Single and multi-actuator tests on mechanical components and large-scale structures

- Fatigue tests to define the life of a component

- Application of a load spectrum to simulate a real stress condition

- Static and dynamic tests to verify the integrity of components and large-scale structures subjected to the real operating conditions

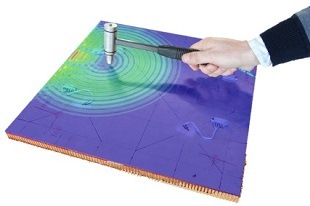

- Detection and monitoring of crack propagation during a fatigue test (non-destructive methods, microscope, crack gauges, etc.)

- Determination of the influence of several technological parameters on the fatigue resistance

- Laboratory testing of structural health and usage monitoring systems under varying load and environmental conditions

- On-platform testing

Fatigue tests for biomedical applications and multi-scale mechanical characterization of biological tissues

- Static and fatigue tests to verify the resistance of limb prosthesis

- Performance optimization of leg prosthesis for sportive applications

- Static tests performed outside and inside a synchrotron to determine meso and micro characteristics of biological tissues

- Detection of microdamage mechanisms

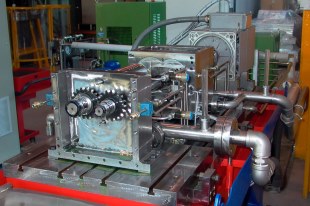

Gear fatigue tests: Tooth Bending Fatigue, Contact Fatigue (pitting and micropitting), vibration and noise, efficiency, contact pattern and torsional stiffness tests on gears and gear reducers. Several experimental devices are available:

- CENIT 2, a power-recirculating test rig suitable for gear contact fatigue (i.e. pitting), scuffing and bending fatigue tests on running gears Schenck mechanical resonance pulsator for tooth root bending fatigue tests with a STBF (Single Tooth Bending Fatigue) approach.

- VIBRU, Motor / brake test rig up to 100 kW, reconfigurable on plates, for measurements of Transmission Error and Noise

- Electric power recirculation test rig, DC motor and brake, 30 kW, 3,000 rpm reconfigurable on plates

Dynamical characterization of components

- Tests to analyze the dynamical behavior (frequency response, mechanical impedance, fatigue resistance, etc.) of components and systems using electromechanical shakers

- Development of control systems for vibrations on “Smart structures”