Several Laser Powder Bed Fusion (LPBF) systems are present at MeccPolimi allowing our researchers and industrial partners to explore different material, geometry and part size solutions. The machine parkour is composed of industrial and research grade equipment able to process from standard alloys such as AISI 316, AlSi10Mg, and Ti6Al4V to more challenging ones namely Cu-, Zn-, and NiTi alloys, and even towards exotic materials such as the lunar regolith.

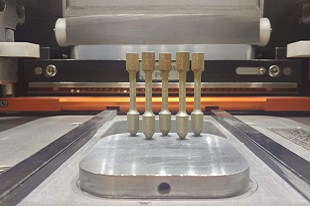

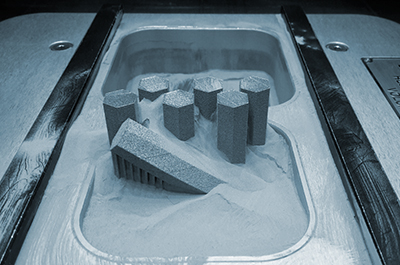

Amongst the LPBF machines available at MeccPolimi, Renishaw AM250 provides a 250 mm x 250 mm x 300 mm build volume. The system operates with a 200 W single mode modulated fiber laser. Novel materials are tested on the AM250 with small quantities of powder employing the Reduced Build Platform (RBV) system with a limited build volume of 78 mm x 78 mm x 50 mm. The 3DNT LLA150 is a research grade industrial LPBF machine made for the requirements of the MeccPolimi researchers. The build volume is ø150 mm x 150 mm. The open hardware and software architecture allows the MeccPolimi researchers to test novel laser temporal and spatial beam shaping possibilities as well as inline monitoring and control strategies. The LLA150 is fitted with a novel laser source able to produce Gaussian to ring beam shapes with up to 1 kW power. MeccPolimi researches have also developed several open LPBF prototype systems demonstrating novel process capabilities. Amongst the prototypes, Powderful provides graded multi-material processing solutions as well as novel laser wavelengths such as green. Penelope operates with multiple coaxial and lateral sensors to recognize and correct the process defects thanks to a patented on-board grinding solution. Grisù, on the other hand, provides high and evenly distributed preheating temperatures up to 1000°C by lowering the small powder bed into an induction coil.